Custom 3D Printed Snorkel for Suzuki Stockman (1981)

Identifying the Challenge

We were approached to create a custom snorkel for a 1981 Suzuki Stockman. The existing pipe sat externally on the vehicle, leaving it vulnerable to water intake if submerged, and it didn’t suit the overall look of the car. Off-the-shelf snorkels weren’t available for this model, so a bespoke, one-off solution was needed — the perfect opportunity to put additive manufacturing to work.

Capturing the Data

Using our Artec Leo 3D scanner, we captured high-resolution scans of the vehicle. This gave us all the detail needed to ensure the snorkel design would integrate seamlessly with the Stockman — fitting tightly to the body, sealing correctly, and avoiding interference with other components.

The design brief required a two-part snorkel that would mount to the car, seal against the body, and suit a standard snorkel head.

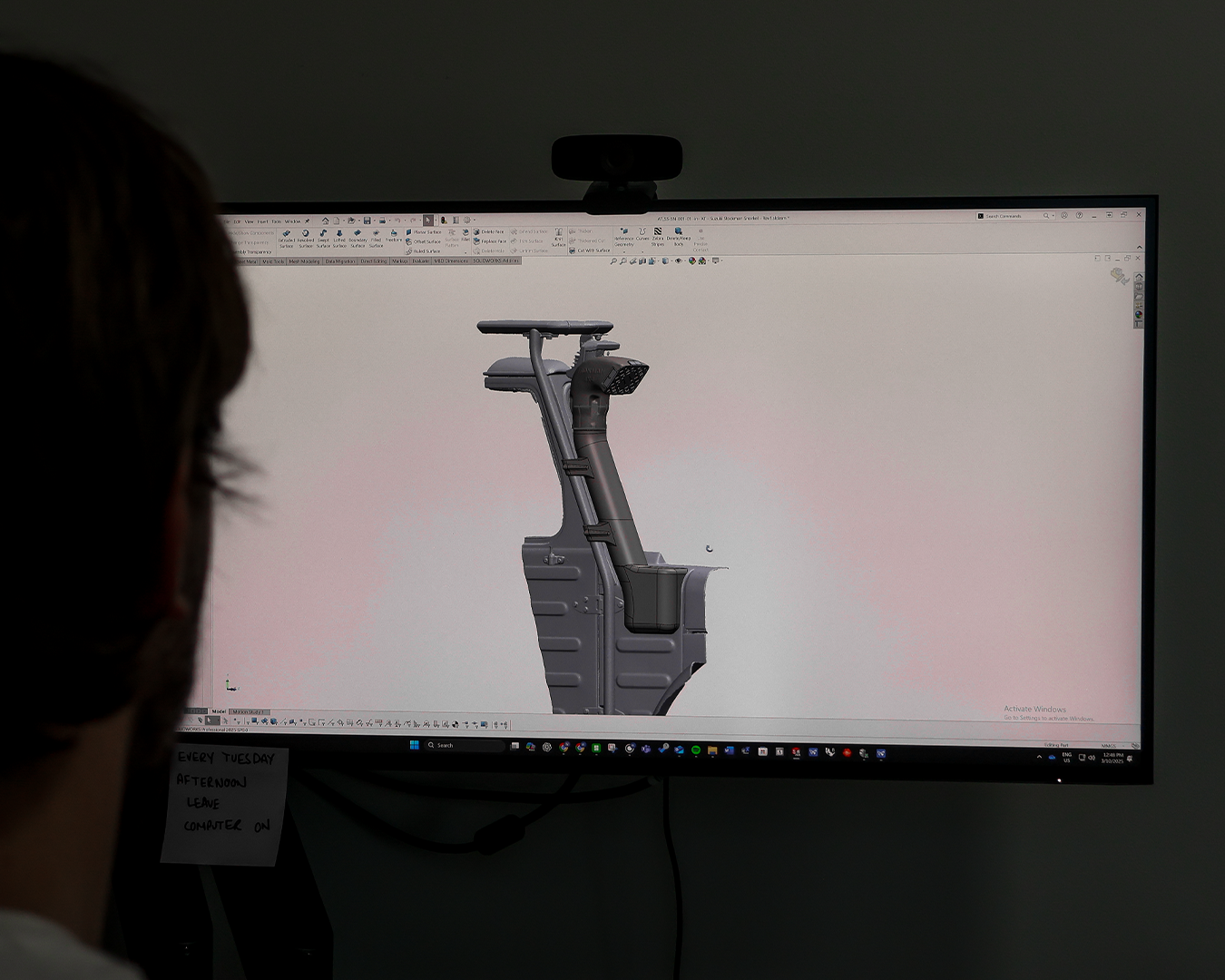

Design and Print Setup

From the scan, a detailed CAD model was created to match the vehicle’s body lines and mounting points. Once approved, the file was prepped for print.

For production, we used our new H2D-Pro 3D printer — chosen for its large build volume, speed, and reliability in producing ASA parts. ASA is strong, UV-stable, and ideal for automotive components that need to withstand outdoor conditions.

Final Print and Solution

With everything in place, the snorkel was printed across just 1.5 days — a fast turnaround considering the size and complexity of the component. The two sections were finished and ready for fitment straight from the Forma 3D Print Lab.

The final result? A custom snorkel that fit the vehicle perfectly, matched the aesthetic, and offered full functionality — all made to order, with no need for costly tooling or outsourcing.

Keeping Custom Builds Local

This project is a great example of how 3D scanning, CAD design, and additive manufacturing can deliver tailored solutions where off-the-shelf parts don’t exist. For unique vehicles and specialist builds, local manufacturing can provide accurate, reliable, and fast results that are both functional and visually on point.

Wanting to do a similar project? Get in contact with our friendly team today.

Location: 11 Mort Street, Toowoomba, QLD

Email: admin@forma3d.com.au

Phone: (07) 4588 6659