Replacing Obsolete HID Lamp Insulators Using 3D Printed Rigid 10K Resin

When replacement parts are only available as part of full assemblies, 3D printing becomes a smarter, more sustainable alternative. That was the case for Queensland Electrical Solutions when they approached Forma 3D with a frustrating problem, replacing just one small but critical part inside a 2000 metal halide lighting system.

The Challenge

Queensland Electrical Solutions needed replacement HID lamp insulators. While technically still available, they could only be purchased as part of a complete lighting kit—making the process costly and wasteful. Most of their lighting hardware still worked perfectly. They simply needed new insulators.

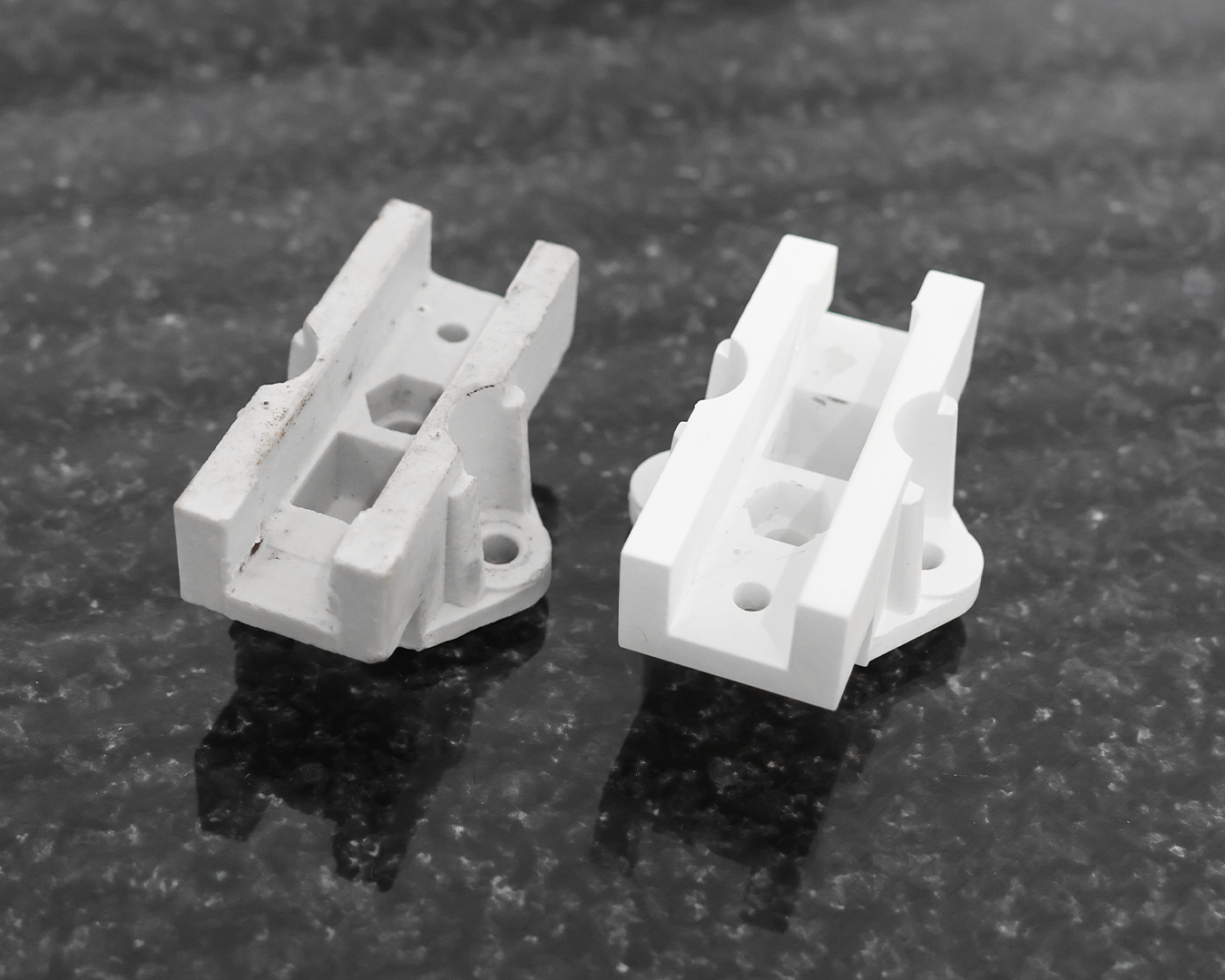

They brought us the only surviving insulator and asked: can you recreate this?

This type of part re-creation is exactly what Forma 3D specialises in capturing the geometry, recreating the part, and manufacturing a precise, reliable replacement.

Capturing the Part

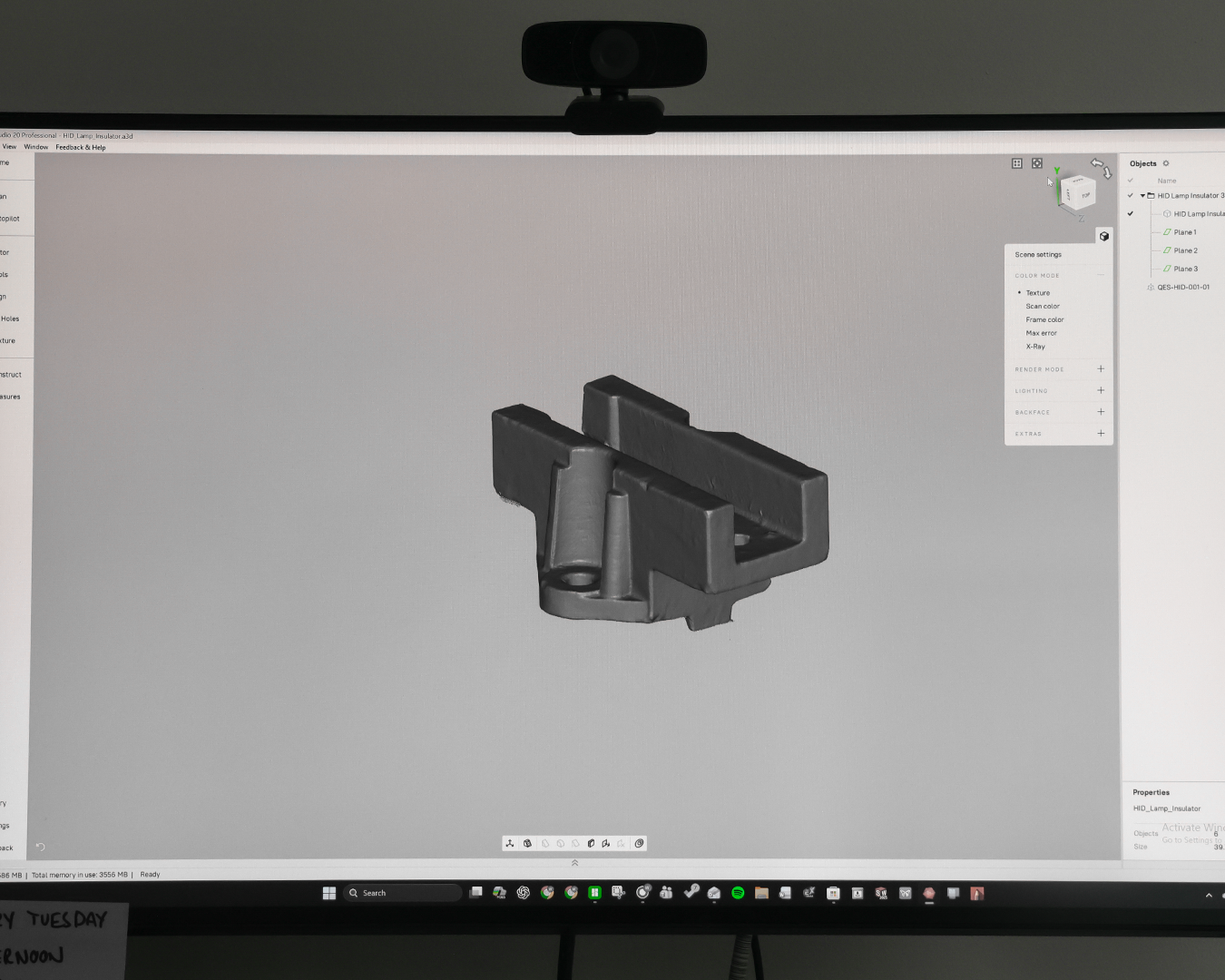

The original insulator had clear signs of heat exposure and long-term wear, making manual measurement unreliable. We used high-resolution 3D scanning to digitise the part and capture the complete geometry, even compensating for deformation.

Using the scan, we reconstructed the part in CAD - restoring key dimensions, critical alignment features, and mating surfaces.

Prototyping & Testing

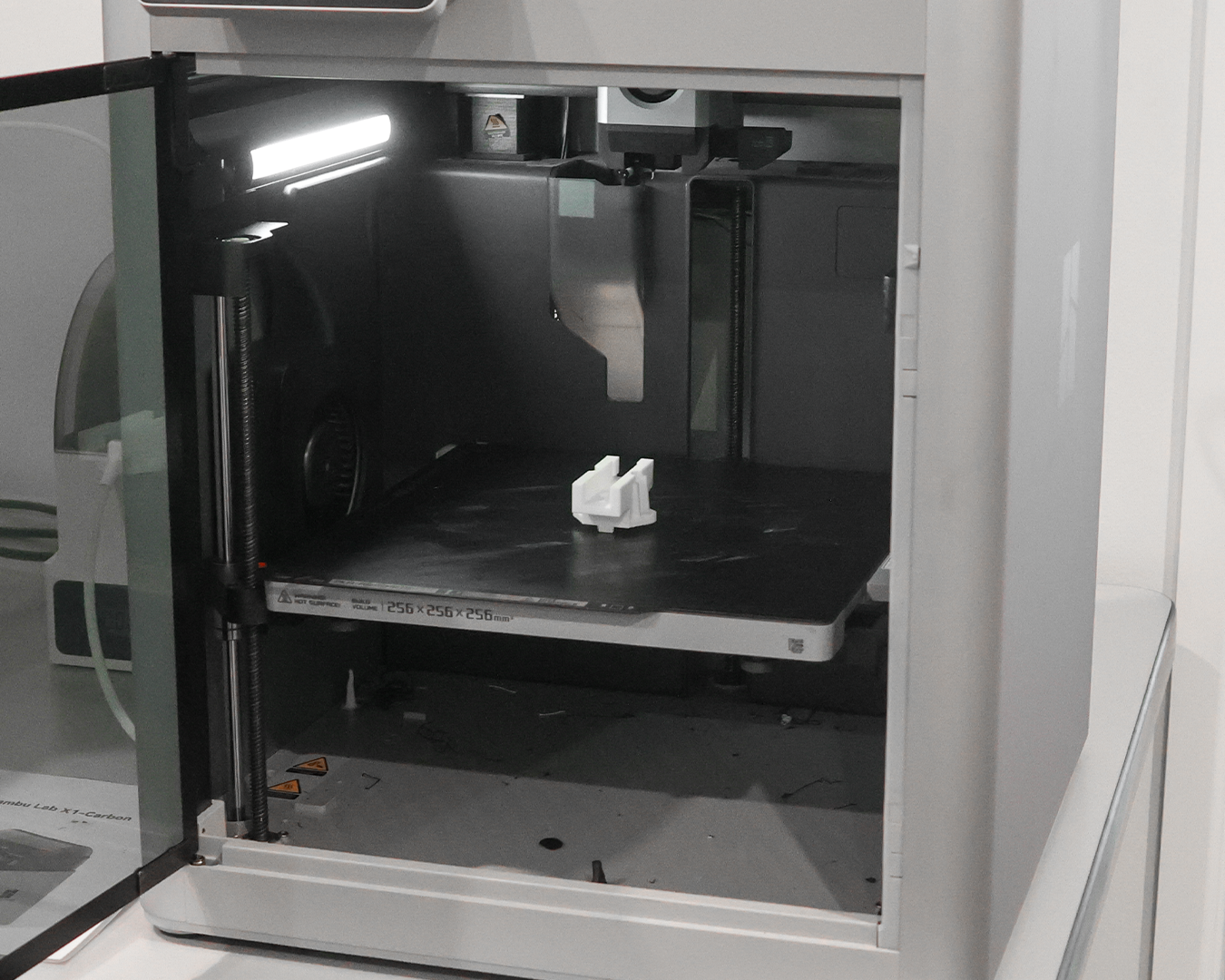

Before moving to production, we printed a prototype using PLA. This allowed us to check fitment inside the lamp housing and verify dimensions and tolerances.

After confirming everything was spot-on, we selected the final manufacturing material—Rigid 10K Resin.

This resin offers:

Exceptional stiffness

High heat resistance

Dimensional stability

Excellent insulating properties

These qualities made it ideal for the application. It would handle temperature, hold shape under pressure, and provide the long-term reliability the component demanded.

Final Product

Using Rigid 10K Resin, we printed a full set of HID insulators. The prints came out clean, required minimal post-processing, and slotted precisely into the existing assemblies. Thanks to a solid CAD base and material built for performance, the components delivered a tight, secure fit, without the need to buy full kits.

The parts were delivered and installed without issue. They performed as expected and helped extend the life of otherwise functioning equipment. It’s a good example of how modern 3D technology can solve low-volume replacement problems quickly, accurately, and cost-effectively.

Need Something Recreated?

At Forma 3D, we help businesses keep machines, vehicles and systems running when original parts are no longer available. Whether it’s for restoration, repair, or redesign - if you have the part, we can scan, model and print a replacement.

Get in contact with our friendly team today.

Location: 11 Mort Street, Toowoomba, QLD

Email: admin@forma3d.com.au

Phone: (07) 4588 6659